Understanding Electromagnetic Shielding Materials: Options, Applications, and Best Practices

1. Introduction to Electromagnetic Shielding Materials

1.1 What are Electromagnetic Shielding Materials?

Electromagnetic shielding materials are specialized substances designed to protect devices and environments from electromagnetic interference (EMI). EMI encompasses a range of disturbances generated either by external sources, such as electrical circuits, or by internal components within devices. These materials prevent unwanted electromagnetic waves from penetrating sensitive electronics, ensuring optimal functionality and safety. Typical materials used for this purpose include a variety of electromagnetic shielding materials, including metals like copper and aluminum, composites, and innovative coatings.

1.2 Importance in Modern Technology

In today’s technology-driven world, the importance of electromagnetic shielding cannot be overstated. With the increasing prevalence of electronic devices—from smartphones to smart home gadgets—ensuring that these devices do not suffer from interference is crucial. EMI can degrade performance, cause data loss, and even lead to complete failure. Shielding materials are essential in various applications, including telecommunications, automobiles, industrial machinery, and medical devices, all of which require robust protection against EMI to function reliably.

1.3 Overview of Common Uses

Electromagnetic shielding materials are utilized in an array of industries and applications. Some of the most common uses include:

- Telecommunications: Preventing interference in devices like phones and routers.

- Medical Equipment: Essential for MRI machines and other diagnostic tools where precision is paramount.

- Aerospace: Protecting avionics from external electromagnetic sources.

- Consumer Electronics: Ensuring smartphones, tablets, and laptops operate without interference.

- Automotive: Shielding critical electronic systems in modern vehicles.

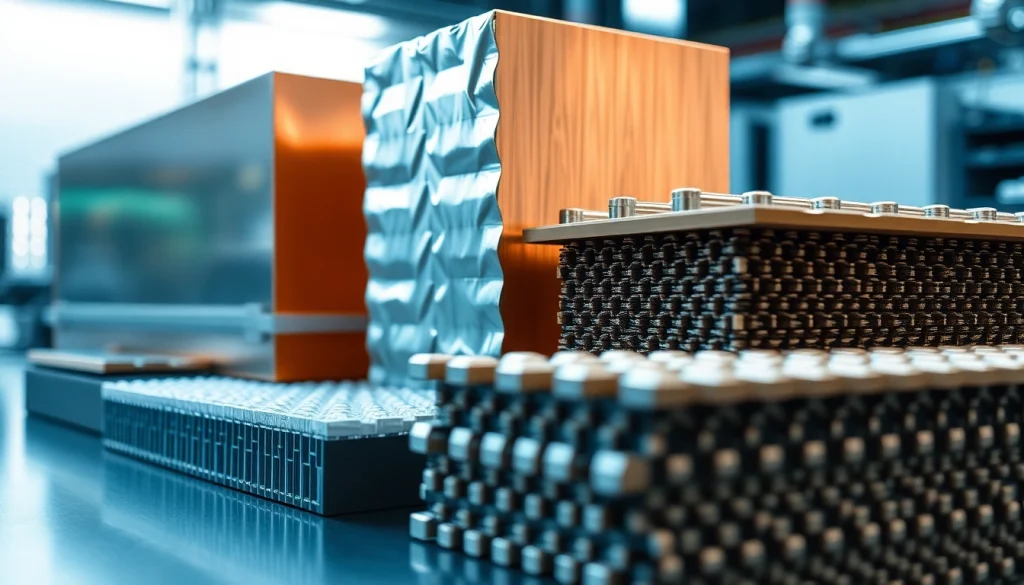

2. Types of Electromagnetic Shielding Materials

2.1 Metals: Copper, Aluminum, and Steel

Metals are amongst the most effective materials for electromagnetic shielding due to their high electrical conductivity. Copper is often regarded as the gold standard in EMI shielding because of its excellent performance in attenuating both magnetic and electrical waves. Aluminum is another popular choice due to its lighter weight and lower cost compared to copper, while steel provides robustness in structural applications.

In addition to these metals, alloys such as nickel-copper also play an essential role, particularly in environments requiring heightened corrosion resistance or specific mechanical properties.

2.2 Non-Metallic Options: Composites and Polymers

Non-metallic materials have gained prominence in the EMI shielding domain. Composites mix conductive materials, such as carbon fibers or metal-coated fibers, with polymers to create lightweight and flexible solutions. These non-metallic materials can be advantageous in applications where mobility and wear resistance are needed without compromising on shielding effectiveness. Examples include conductive silicone and epoxy coatings that can be applied to various surfaces to enhance their EM shielding capabilities.

2.3 Innovative Coatings and Foams

Recent advancements in technology have led to the development of innovative coatings and foams. Conductive inks, for instance, can be printed onto surfaces to create a flexible shield without adding significant weight. Metal foams and mesh are also becoming more common due to their lightweight nature and effectiveness in blocking a wide range of electromagnetic frequencies. These materials are especially useful in aerospace and automotive applications, where weight savings can translate into fuel efficiency.

3. Selecting the Right Shielding Material

3.1 Factors to Consider: Conductivity and Cost

When selecting an electromagnetic shielding material, several factors must be considered to ensure optimal performance. The level of conductivity is paramount; higher conductivity materials typically provide better shielding efficiency. However, performance must be balanced with cost, as premium metals like copper can significantly increase project budgets.

3.2 Evaluating Performance Metrics

Evaluating the performance of shielding materials involves analyzing several key metrics, including:

- Shielding Effectiveness: Measured in decibels (dB), it indicates how well a material blocks electromagnetic waves.

- Frequency Range: Different materials perform better across varied frequencies, and understanding specific application requirements is essential.

- Durability: The material’s ability to withstand environmental extremes and potential wear and tear is crucial for long-term applications.

3.3 Industry-Specific Recommendations

Selecting the right shielding material often requires industry-specific knowledge. For instance, in the medical field, lightweight and highly effective copper materials might be favored, while automotive applications may lean towards more robust and cost-effective aluminum alloys. Understanding regulatory standards and performance specifications for each industry is vital to ensure compliance and reliability.

4. Installation and Implementation Best Practices

4.1 Techniques for Effective Application

Proper installation of electromagnetic shielding materials is essential to achieve the desired performance. Techniques may include:

- Grounding: Ensuring that the shielding material is adequately grounded to eliminate potential electrical discrepancies.

- Sealing Joints: Utilizing conductive adhesives or gaskets can help to maintain the integrity of shielding effectiveness across seams and joints.

- Layering: In some applications, multiple layers of different materials may be used to optimize performance across a broader frequency range.

4.2 Common Challenges and Solutions

While implementing shielding materials, several challenges may arise:

- Material Compatibility: Different materials may react chemically, negatively impacting performance. It’s essential to validate compatibility before installation.

- Cost Overruns: Quality shielding can be expensive; advanced planning and material sourcing can help mitigate budget issues.

4.3 Maintenance and Long-Term Considerations

Post-installation maintenance is integral to ensuring long-term effectiveness. Regular inspections for wear and degradation, particularly in high-stress environments such as aerospace and automotive sectors, should be a routine practice. Considerations for environmental exposure and conditions must inform material selections and maintenance schedules.

5. Future Trends in Electromagnetic Shielding Materials

5.1 Emerging Technologies and Innovations

The field of electromagnetic shielding is evolving rapidly, driven by innovation in materials science. Researchers are exploring the potential of materials like metamaterials, which can manipulate electromagnetic waves in unprecedented ways. Furthermore, the integration of nanotechnology into shielding solutions is expected to enhance performance while reducing weight.

5.2 Environmental Impact and Sustainability

As sustainability becomes a central theme across industries, the demand for eco-friendly shielding solutions is on the rise. Manufacturers are exploring recyclable materials and processes that minimize environmental footprints while maintaining performance effectiveness. Using biodegradable composites in shielding may soon become standard practice.

5.3 The Future of EMI Shielding in Various Industries

In the future, we can expect to see broader adoption of advanced shielding materials across diverse sectors. For example, the automotive industry is likely to see increased integration of lightweight and flexible shielding solutions as the trend towards electric vehicles continues. In the medical field, the push for more portable and efficient devices will enhance the need for high-performance EMI shielding materials.