Coastal Metal Roofing: The Ideal Solution for Durability and Style by the Shore

Understanding Coastal Metal Roofing

What is Coastal Metal Roofing?

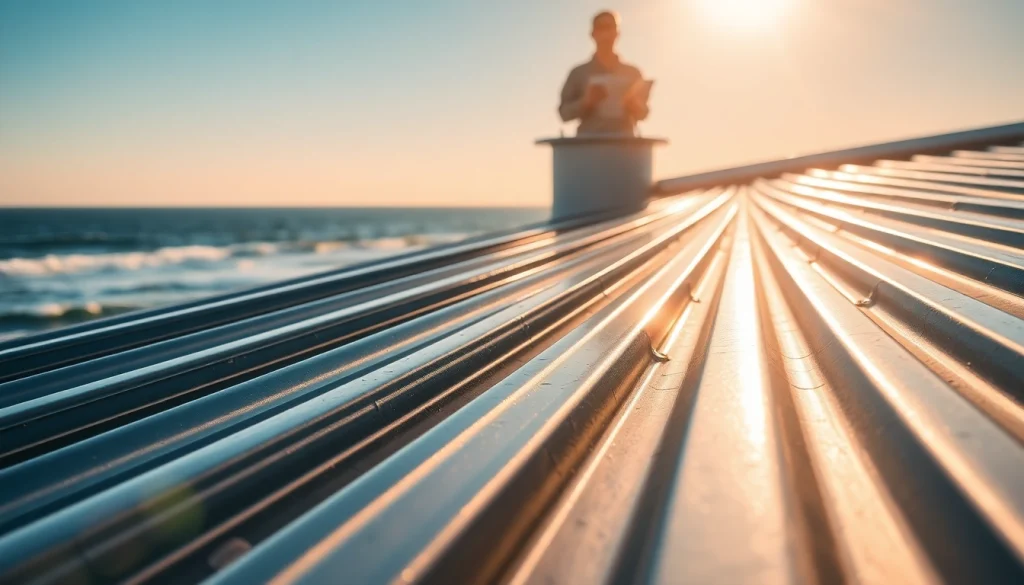

Coastal metal roofing refers to specially designed roofing systems that utilize metal materials suitable for coastal environments. These roofs are engineered to withstand harsh oceanic conditions, including high winds, salt exposure, and heavier precipitation associated with storms. Unlike traditional roofing materials, coastal metal roofing offers a superior blend of durability, aesthetic appeal, and energy efficiency, making it an increasingly popular choice for homeowners and commercial builders alike. The application of coastal metal roofing ensures that properties can maintain structural integrity and visual charm despite the challenges presented by their coastal locations.

Benefits of Using Metal Roofing in Coastal Areas

Metal roofing is preferred in coastal areas for numerous reasons:

- Durability: Metal roofs are exceptionally resistant to rust, corrosion, and extreme weather. Modern coatings and finishes can fend off salt degradation and rust, ensuring a long lifespan.

- Lightweight: Unlike traditional materials like tiles or asphalt shingles, metal roofing is lightweight, decreasing structural load and simplifying installation.

- Energy Efficiency: Metal roofing systems reflect solar radiant heat, leading to lower energy costs by keeping buildings cooler in the summer.

- Environmental Impact: Many metal roofs are made from recycled materials and can be fully recyclable at the end of their life cycle, promoting sustainability.

- Aesthetics: These roofs are available in various styles and colors, allowing homeowners to express their design preferences while benefiting from all the practical advantages.

Types of Metal Roofing Materials for Coastal Use

Diverse metal roofing materials cater to different aesthetics and functional needs in coastal areas. These include:

- Steel: Galvanized or galvalume steel is prevalent due to its affordability and resistance to corrosion. This material typically requires a protective coating to prevent rust.

- Aluminum: Lightweight and naturally resistant to corrosion, aluminum is ideal for coastal environments characterized by high humidity and salty air.

- Copper: As one of the most durable materials, copper develops a patina over time, enhancing its corrosion resistance while providing a distinct aesthetic.

- Stainless Steel: Offering superior performance, stainless steel is less susceptible to corrosion and staining, making it a long-lasting option in severely affected coastal areas.

Installation Considerations for Coastal Metal Roofing

Preparing Your Home for Metal Roofing Installation

Proper preparation for the installation of coastal metal roofing is crucial to maximizing performance and longevity. Important preparation steps include:

- Inspection of Structural Integrity: Assess the existing roof structure for damage and ensure it can support the weight of the metal roofing.

- Weather Considerations: Schedule installations during dry weather windows to avoid complications from rain or high winds during the process.

- Ventilation and Insulation: Ensure adequate ventilation and insulation are factored into the design to improve energy efficiency and mitigate condensation issues that can lead to rust.

Hiring Professionals versus DIY Installation

When deciding between hiring professionals and taking a DIY approach for the installation of coastal metal roofing, consider the following:

While DIY installation can save money, it often lacks the precision and efficiency of professional service. Roof installation is not just about placing panels; it involves precise measurements, proper sealing, and an understanding of local building codes. On the other hand, hiring professionals ensures that the roofing is installed correctly and safely, which can lead to long-term savings by preventing leaks and other issues.

Common Challenges in Coastal Roofing Installations

Coastal metal roofing installations can present unique challenges:

- Harsh Conditions: High winds and heavy rains can complicate installations, requiring careful planning and timing.

- Material Handling: Care must be taken to prevent scratches and damage to metal panels during transportation and installation.

- Regulatory Compliance: Coastal areas often have specific building codes and regulations designed to withstand storms; understanding these is essential for compliance.

Maintenance Tips for Coastal Metal Roofing

Routine Checks and Inspections

Regular inspections are vital for preserving the integrity and aesthetics of coastal metal roofs. Homeowners should perform checks at least bi-annually, focusing on:

- Fasteners and Panel Seams: Ensure that all fasteners are tight and that seams are properly sealed.

- Rust and Paint Damage: Look for signs of rust or paint degradation and address them immediately to prevent further issues.

- Gutters and Downspouts: Clear any debris that may block drainage pathways, particularly after storms.

Cleaning and Care for Metal Roofs

To maintain the appearance and functionality of a coastal metal roof, cleaning should be undertaken periodically. Simple methods include:

- Washing with Mild Detergent: A gentle wash with detergent and water can remove salt and dirt buildup.

- Using a Soft-Bristle Brush: Avoid abrasive materials that can scratch the metal surface.

- Inspecting for Growth: Look for moss or algae growth, especially in shaded areas, and address it promptly.

Addressing Potential Damage from the Elements

Natural wear and tear is inevitable in coastal environments. Homeowners should know how to address:

- Rust Prevention: Regular inspection and maintenance can reduce rust development. Repainting or resealing panels may be necessary based on the material used.

- Punctures and Dents: Address any punctures promptly; they can compromise the roof’s integrity. Small dents may not require immediate action but should be regularly monitored.

- Seam Failure: Ensure that panel seams remain intact and reseal as necessary to prevent leaks.

Cost Analysis of Coastal Metal Roofing

Initial Investment and Long-Term Savings

The upfront cost of installing coastal metal roofing can be higher than traditional materials; however, the long-term savings can be significant. Considerations include:

- Longevity: Metal roofing systems can last fifty years or more, significantly outlasting other types that typically require replacement within 15-30 years.

- Energy Savings: Reduced energy costs due to the energy-efficient nature of metal compared to traditional shingles can save homeowners money over decades.

- Minimal Maintenance Costs: Thanks to their durable construction, metal roofs require less frequent repairs, leading to overall lower long-term investment.

Factors Affecting Metal Roofing Costs in Coastal Areas

When considering the costs associated with metal roofing in coastal areas, a few factors come into play:

- Material Choice: Prices will vary significantly depending on whether you opt for aluminum, zinc, or steel.

- Installation Complexity: Roofs with complicated angles or additional features such as skylights may increase labor costs.

- Local Market Pricing: Regional price differences can influence overall spending; it’s wise to obtain multiple quotes from local contractors.

Comparative Cost: Metal vs. Traditional Roofing

When comparing costs, consider both installation and long-term expenses:

| Roofing Material | Initial Cost (per sq. ft.) | Average Lifespan | Maintenance Cost (Annual) | Energy Savings |

|---|---|---|---|---|

| Metal Roofing | $5-$12 | 40-70 years | Low | High |

| Asphalt Shingles | $1-$4 | 15-30 years | Moderate | Moderate |

Future Trends in Coastal Metal Roofing

Innovations in Metal Roofing Technology

As technology advances, the metal roofing industry continues to evolve. Recent innovations include:

- Advanced Coatings: New coatings are developed that further resist corrosion and UV damage, extending roof life without compromising aesthetics.

- Integrated PV Systems: Photovoltaic (PV) roofing integrates solar technology directly into metal panels, providing energy efficiency alongside aesthetics.

- Improved Manufacturing Techniques: Techniques that enhance durability while reducing costs are becoming more common across the industry.

Sustainability Practices in Metal Roofing Manufacturing

More metal roofing manufacturers are prioritizing sustainability. Key practices include:

- Recycled Materials: Many companies use a significant percentage of recycled metal in their roofing products, minimizing environmental impact.

- Energy-Efficient Production: Modern plants are increasingly focused on reducing energy consumption during manufacturing processes.

- Environmental Certifications: Look for roofing products certified by organizations like Energy Star and Cool Roof Rating Council, indicating better performance and efficiency.

Design Trends and Aesthetic Options in Coastal Roofing

As homeowners seek to enhance their property’s curb appeal, design trends in metal roofing show exciting developments:

- Bold Colors: Bright and bold color options reflect personal style while helping with heat reflectance, promoting energy efficiency.

- Textured Finishes: Textured coatings mimic traditional materials like wood or tile while providing the durability of metal.

- Custom Designs: Sophisticated manufacturing allows for custom shapes and styles, making unique designs more accessible for coastal homes.