Top-Tier Powder Coating Birmingham Services for Stunning Finishes

Understanding Powder Coating: A Comprehensive Guide

Powder coating has rapidly gained traction as an efficient and durable finishing option for various metal products. It offers a long-lasting finish that not only enhances the aesthetic appeal but also provides protection against corrosion and wear. For those seeking high-quality powder coating Birmingham services, understanding the fundamentals can make a significant difference in achieving the desired results.

What is Powder Coating?

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paints that require a solvent to keep the binder and pigments in a liquid suspension form, powder coating involves a heat application process that allows it to cure and form a hard finish. During powder coating, particles of the powder are sprayed onto a surface that is electrically charged, which helps to ensure an even distribution and a secure bond. Once the powder coating is applied, the item is then placed in a curing oven, where it melts and chemically reacts to create a durable, protective layer.

How Does Powder Coating Work?

The powder coating process involves several critical steps:

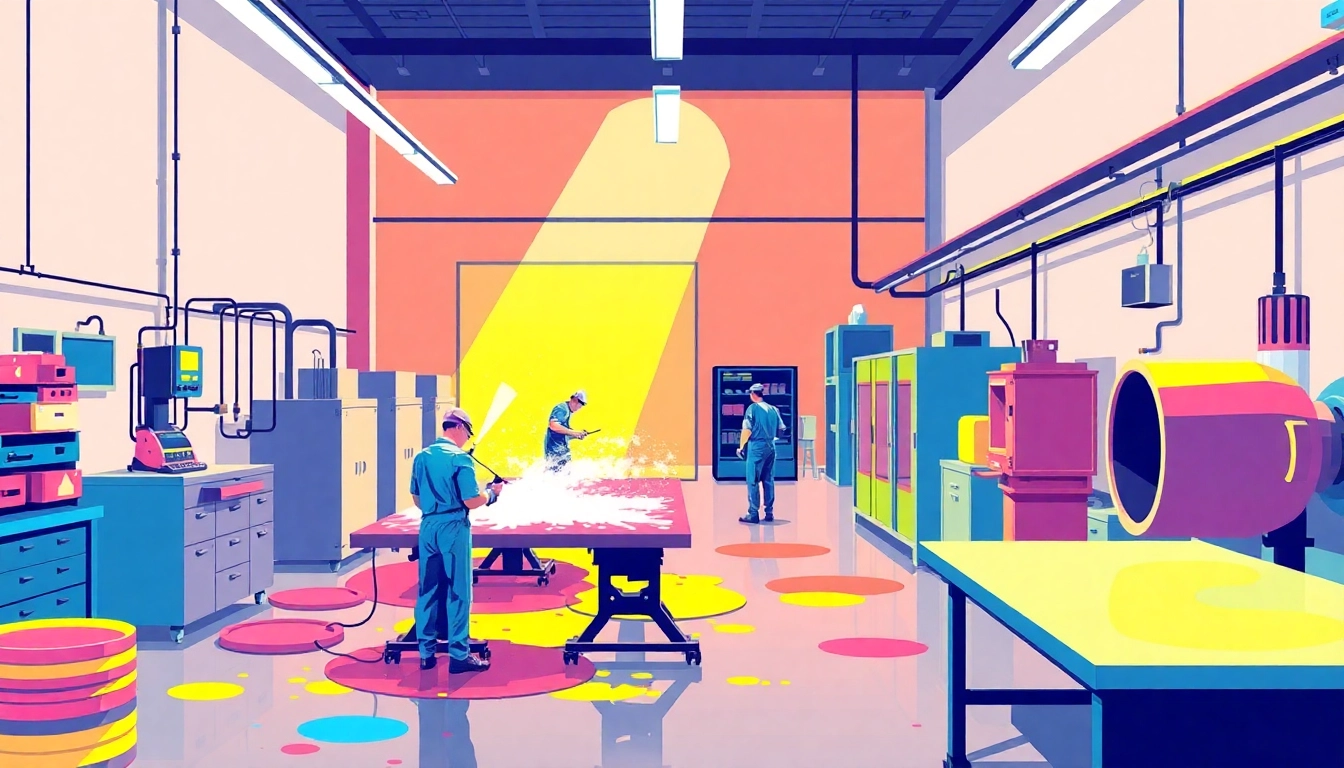

- Preparation: The surface of the item must be properly cleaned and prepped to ensure optimal adhesion. This often involves sandblasting, cleaning, or priming the surface to remove any oils, dirt, or rust.

- Application: The powder is then applied using an electrostatic spray gun. The gun charges the powder particles, making them electrically attracted to the grounded object.

- Curing: After application, the coated product is placed in an oven where it is heated to a specific temperature (usually between 350°F to 400°F). This heat causes the powder to melt and flow into a continuous film that bonds to the surface.

- Cooling: Once the item is removed from the oven, it is cooled, solidifying the coating into a hard finish.

Advantages of Choosing Powder Coating Birmingham

Opting for powder coating services in Birmingham provides a wide range of advantages, making it a preferred choice over traditional painting methods:

- Durability: Powder coating creates a tougher finish that can withstand chipping, scratching, and corrosion.

- Environmentally Friendly: Unlike liquid paints, powder coatings contain no solvents and emit negligible amounts of volatile organic compounds (VOCs).

- Aesthetic Variety: Powder coating is available in a vast array of colors and finishes, making it easy to match any design style.

- Efficiency: The application process is faster, and pieces can be handled more quickly after curing, enhancing overall productivity.

Key Industries Utilizing Powder Coating

Aerospace and Automotive

In the aerospace and automotive industries, powder coating is utilized for both functional and aesthetic purposes. Aircraft components and automobile parts are often powder coated to protect against the harsh environments they encounter, such as extreme weather conditions and wear. The automotive industry benefits from the ability to achieve vibrant colors and finishes while ensuring components are durable against corrosion.

Furniture and Interior Design

The furniture industry sees powder coating as a viable option for metal furniture items, including chairs, tables, and light fixtures. It provides an attractive finish while ensuring long-lasting durability. The smooth finish achieved through powder coating is also easier to clean and maintain compared to painted surfaces, making it ideal for interior designs that demand both aesthetics and functionality.

Building and Construction

In the construction sector, powder coating is frequently applied to components such as railings, gates, and multiple fixtures. The robust nature of the powder coat ensures that these structures can withstand the rigors of outdoor environments, providing lasting color and protection against UV damage and rust.

Cost Analysis of Powder Coating in Birmingham

Average Pricing Breakdown

The average cost of powder coating varies based on several factors, including the size of the item, the complexity of the job, and the chosen finish. Generally, customers can expect to pay anywhere from £50 to £430 per item, with many paying around £170 for standard applications.

Factors Influencing Cost

Several key factors can influence the cost of powder coating services:

- Preparation Requirements: Items that require extensive cleaning or repairs will incur additional costs for the preparatory work.

- Size and Volume: Larger items or bulk orders may attract bulk pricing discounts, while smaller or one-off jobs may cost more on a per-item basis.

- Type of Finish: Specialty finishes, such as metallic or textured coatings, tend to be more expensive compared to standard colors.

Comparing Powder Coating and Traditional Painting Costs

When comparing powder coating to traditional painting methods, it’s essential to consider the long-term value of each option. The initial cost of powder coating may be higher, but the long-lasting durability, reduced maintenance, and improved aesthetic appeal often justify the expense in the long run. For example, powder coating typically lasts longer than paint, which may require more frequent touch-ups or reapplications.

Choosing the Right Powder Coating Service in Birmingham

What to Look for in a Service Provider

Selecting the right service provider for your powder coating needs is crucial for ensuring quality results. Here are some key considerations:

- Experience and Reputation: Look for companies with a solid track record and positive customer reviews.

- Facilities and Equipment: A well-equipped facility with the latest technology can significantly influence the quality of the finish.

- Variety of Services: Choose a provider that offers a range of finishes and services to meet your specific needs.

Questions to Ask Before Hiring

Before finalizing your choice of a powder coating service, consider asking the following questions:

- What types of materials can you powder coat?

- What is your turnaround time for projects?

- Can you provide samples of previous work or references from past customers?

Customer Reviews and Case Studies

One of the best ways to gauge the quality of a powder coating service is by examining customer reviews and case studies. Look for testimonials that highlight the provider’s attention to detail, customer service, and overall satisfaction with the finished product. Additionally, case studies can offer insights into how the service has handled specific challenges or large projects.

Maintaining Your Powder Coated Items

Best Practices for Care and Cleaning

To ensure the longevity of powder-coated surfaces, it’s essential to implement proper care routines. Here are some best practices:

- Regular Cleaning: Use mild soap and warm water to clean surfaces, avoiding abrasive materials or harsh chemicals that can damage the coating.

- Avoid Scratching: Use soft cloths or sponges to prevent scratching the surface during cleaning.

- Inspect Periodically: Regularly inspect items for any signs of wear or damage, allowing for early interventions.

How Long Does Powder Coating Last?

The lifespan of a powder-coated finish can vary depending on several factors, such as the quality of the application and the environmental conditions it faces. Generally, high-quality powder coatings can last between 10 to 25 years. However, in optimal conditions, including protection from harsh UV exposure and extreme weather, many finishes can significantly exceed this longevity.

Signs of Wear and When to Recoat

Despite its durability, signs of wear may indicate the need for recoating:

- Fading Colors: If the finish loses its vibrancy, it may be time for a refresh.

- Chipping or Peeling: Any noticeable chipping or peeling can compromise effectiveness and aesthetics.

- Rust Formation: If rust appears, it’s critical to address it immediately, as it can spread and damage the underlying material.